When undertaking a project that requires the use of Teflon rods, whether it be for mechanical, electrical, or chemical applications, choosing the right Teflon rod is crucial for the success of your work. Teflon, a brand name for a type of polytetrafluoroethylene (PTFE), is a highly versatile material known for its non-stick properties, chemical resistance, and high-temperature tolerance. These features make Teflon rods popular in a variety of industries, from manufacturing to aerospace and medical fields.

However, with so many different types and grades of Teflon rods available, selecting the correct one can be daunting. This blog post will guide you through the key factors to consider when choosing the right Teflon rod for your project.

Understanding the Basics of Teflon Rods

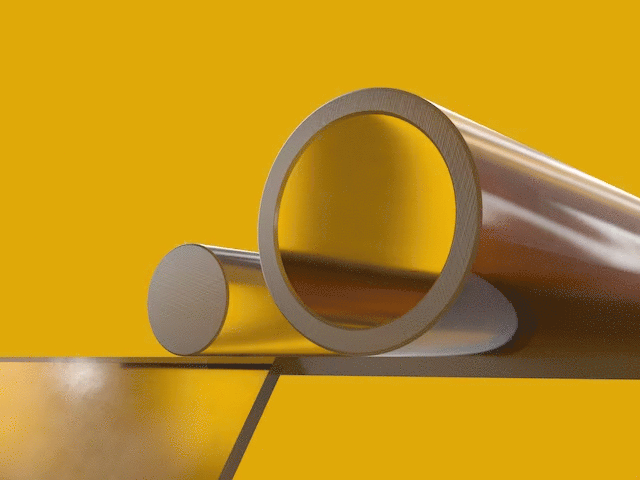

Teflon rods are solid cylindrical pieces of PTFE that can be used in a wide range of applications. These rods come in different sizes, grades, and formulations depending on the specific needs of the project. PTFE is a synthetic polymer made from the polymerization of tetrafluoroethylene monomers. Known for its incredible non-reactivity, high melting point, and excellent electrical insulation properties, Teflon has a broad range of industrial uses.

Here are some characteristics of Teflon rods that are important to consider:

- Chemical Resistance: Teflon is non-reactive to a wide array of chemicals, including acids, bases, and solvents. This makes it a preferred choice for projects that involve exposure to harsh chemicals.

- Temperature Tolerance: Teflon can handle extreme temperatures, from -450°F (-268°C) to 500°F (260°C), making it suitable for both high and low-temperature applications.

- Non-stick Properties: One of the most well-known characteristics of Teflon is its non-stick surface, which prevents adhesion to most substances.

- Electrical Insulation: Teflon is an excellent electrical insulator, making it an ideal material for electrical and electronic components.

Given these features, Teflon rods can be found in a variety of industries, including food processing, pharmaceuticals, chemical manufacturing, and electronics.

Key Factors to Consider When Choosing a Teflon Rod

1. Application Type

The first step in selecting the right Teflon rod is to consider the application or project for which it will be used. Are you dealing with high temperatures? Do you need chemical resistance? Is electrical insulation a priority? Here’s a breakdown of how to choose the right Teflon rod based on your project needs:

- High-temperature applications: If your project involves working in high-temperature environments, such as in industrial machinery or chemical reactors, you’ll need a Teflon rod that can withstand the heat. Standard PTFE rods can handle temperatures up to 500°F (260°C), but for extreme heat resistance, look for specialized grades such as Teflon PFA or Teflon FEP, which offer even better high-temperature properties.

- Chemical resistance: For applications that involve exposure to chemicals or corrosive substances, Teflon’s superior chemical resistance is crucial. PTFE is resistant to most acids, bases, solvents, and oils, making it suitable for use in chemical processing industries. Ensure that the Teflon grade you select is specifically designed for chemical exposure, such as PTFE virgin rods or reinforced PTFE rods.

- Electrical insulation: If you are working with electrical components that require non-conductive materials, Teflon’s electrical insulating properties make it an excellent choice. PTFE is a common material used for wire insulation and circuit boards. For electrical applications, look for Teflon rods with high dielectric strength and ensure they meet industry standards for electrical resistance.

2. Grade and Composition of Teflon

Teflon rods come in different grades and compositions, each suited to specific uses. It is important to select the right grade to meet the specific demands of your project. Some of the most common Teflon grades include:

- Virgin PTFE: This is the most basic form of Teflon, and it is pure PTFE without any fillers or additives. Virgin PTFE is commonly used in applications requiring high chemical resistance, non-stick properties, and electrical insulation.

- Reprocessed PTFE: This is recycled PTFE that has been reused from previous manufacturing processes. While it is more cost-effective than virgin PTFE, its properties may be slightly inferior, especially in terms of uniformity.

- Glass-filled PTFE: In some cases, PTFE rods are filled with glass fibers to enhance their strength and mechanical properties. Glass-filled PTFE rods are stronger and more rigid than virgin PTFE, making them ideal for applications that require greater load-bearing capacity or increased wear resistance.

- Carbon-filled PTFE: Carbon-filled PTFE rods are used when additional strength, anti-static properties, or friction resistance is needed. These rods offer better performance in applications like bearings and seals.

- Bronze-filled PTFE: Bronze-filled Teflon rods offer excellent wear resistance and are often used in applications requiring high-load bearing and low friction.

Selecting the right grade depends on your application’s need for strength, durability, and other specific properties.

3. Size and Dimensions

Teflon rods come in various diameters, lengths, and shapes to suit different projects. It’s important to choose the correct size for your needs, as using the wrong dimensions can result in performance issues.

- Diameter: Measure the required diameter of the rod to ensure it fits within the component or space it’s intended for. Teflon rods are available in a variety of diameters, from small (a few millimeters) to large (several inches).

- Length: You should also select the correct rod length to ensure it covers the area needed for your project. Teflon rods can often be cut to specific lengths, so it’s important to factor in your project’s requirements.

- Tolerance: The tolerance (or the deviation from the exact dimensions) of a Teflon rod should also be considered. For precise applications where tight tolerances are critical, be sure to choose Teflon rods that meet the required specifications.

4. Mechanical Properties

In addition to temperature resistance and chemical compatibility, you’ll want to ensure that the Teflon rod has the necessary mechanical properties for your project. Some key properties to consider are:

- Tensile Strength: The ability of the Teflon rod to resist pulling or stretching forces. If your project involves mechanical stress or loads, you’ll need a rod with high tensile strength.

- Impact Resistance: For applications that require the rod to withstand sudden impacts, such as in heavy-duty machinery, a high-impact-resistant Teflon rod is necessary.

- Flexibility: Some projects require more flexibility in the material, so you may need a Teflon rod that is less rigid or more flexible, especially in applications like seals and gaskets.

5. Cost and Availability

Cost is another important consideration when choosing the right Teflon rod. While virgin PTFE rods may offer the highest quality, they can also be more expensive than reprocessed or filled rods. For some projects, you may be able to opt for a less expensive option without sacrificing too much performance.

Also, consider the availability of the Teflon rod. If your project requires a custom size, you may need to source specialized rods that can be more difficult to find. Plan ahead to ensure that the material you need is readily available.

Conclusion

Choosing the right Teflon rod for your project is a matter of understanding your specific application requirements and matching them with the correct material properties. Whether you’re dealing with high-temperature environments, chemical exposure, or electrical insulation needs, Teflon offers a range of solutions. Consider the grade, size, mechanical properties, and cost of the rod to make the most informed decision for your project.

By carefully assessing the application, chemical resistance, temperature tolerance, and other factors, you can select the ideal Teflon rod that will meet the demands of your project and deliver reliable, long-lasting performance. If you’re looking for high-quality materials, working with a trusted Teflon supplier Singapore ensures access to premium products tailored to your needs, helping to ensure both durability and efficiency in your applications.